A bomba centrífuga para processos químicos é um tipo de bomba utilizada na indústria química para transferir, descarregar, alimentar e lubrificar diversos produtos químicos. Ela opera com base no princípio da força centrífuga, em que a rotação do impulsor lança o líquido para fora, criando uma diferença de pressão que permite que o líquido flua da entrada para a saída.

Pagamento:

TT L/C PayPal Westunion MoneygramOrigem do produto:

China, Anhui provinceCor:

customizedPorta de remessa:

shanghaiTempo de espera:

1 monthMOQ:

1Pacote:

CustomizedCor:

CustomizedMaterial:

Steel/SICTEMPERAÇÃO DE TRABALHO:

-20 to 200℃/The temperature of the transportable medium is 300 ℃Pressão de trabalho:

1.6 MPa

Product overview

The THJ chemical process centrifugal (alkali) pump is a single-stage single-suction cantilever centrifugal pump that has been upgraded and innovated based on the TH pump. It serves as a new standard chemical process pump, replacing the IH and TI pumps. This pump features a single-stage single-suction cantilever structure. In its design, an advanced hydraulic model is adopted, endowing it with high efficiency. As an energy-saving product, its efficiency is 5% higher than that of the IH pump.

Product advantages

1. The flow passage components, including the pump body, pump cover, and impeller, are crafted from high-quality stainless steel. These parts are precision-cast using a novel process, ensuring they are free from impurities, pores, and trachoma. Additionally, high-quality alloy wear-resistant materials like 2205 duplex stainless steel can be opted for.

2. The shaft seal is a proprietary 179 series static corrosion-resistant and wear-resistant mechanical seal. It allows for the selection of single or double end-face mechanical seals, as well as container-type and packing dynamic seals. For the grinding of the sealing surface, materials such as cemented carbide and silicon carbide can be chosen.

3. This pump features a corrosion-resistant and wear-resistant design, capable of transporting liquids containing slurry, crystals, and suspended solid particles smaller than 3mm, with a solid content of less than 10%.

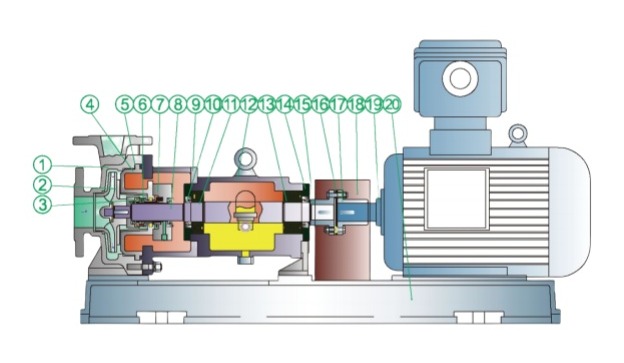

Material List

| Part | Material | Part | Material | Part | Material |

| ①Pump casing | 304/316/316L | ⑧Pump shaft | 2Cr13/3Cr13 | ⑮ Pump coupling | 45# |

| ②Impeller | 304/316/316L | ⑨Bracket | HT200 | ⑯ Diaphragm | 304 |

| ③Static ring | SIC/hard alloy | ⑩Bearing front cover | HT200 | ⑰ Elctric couping | 45# |

| ④Pump cover | 304/316/316L | ⑪ Front bearing | Gcr15 | ⑱ Shield | Hot rolled plate/Aluminum |

| ⑤Gasket | PTFE | ⑫ bearing box | HT200 | ⑲ Motor | As clients requested |

| ⑥Rotating ring | SIC/hard alloy | ⑬ Rear bearing | Gcr15 | ⑳ Plate | HT200 |

| ⑦Gland | 304/316/316L | ⑭ Rear gland of bearing | HT200 |

Structural diagram

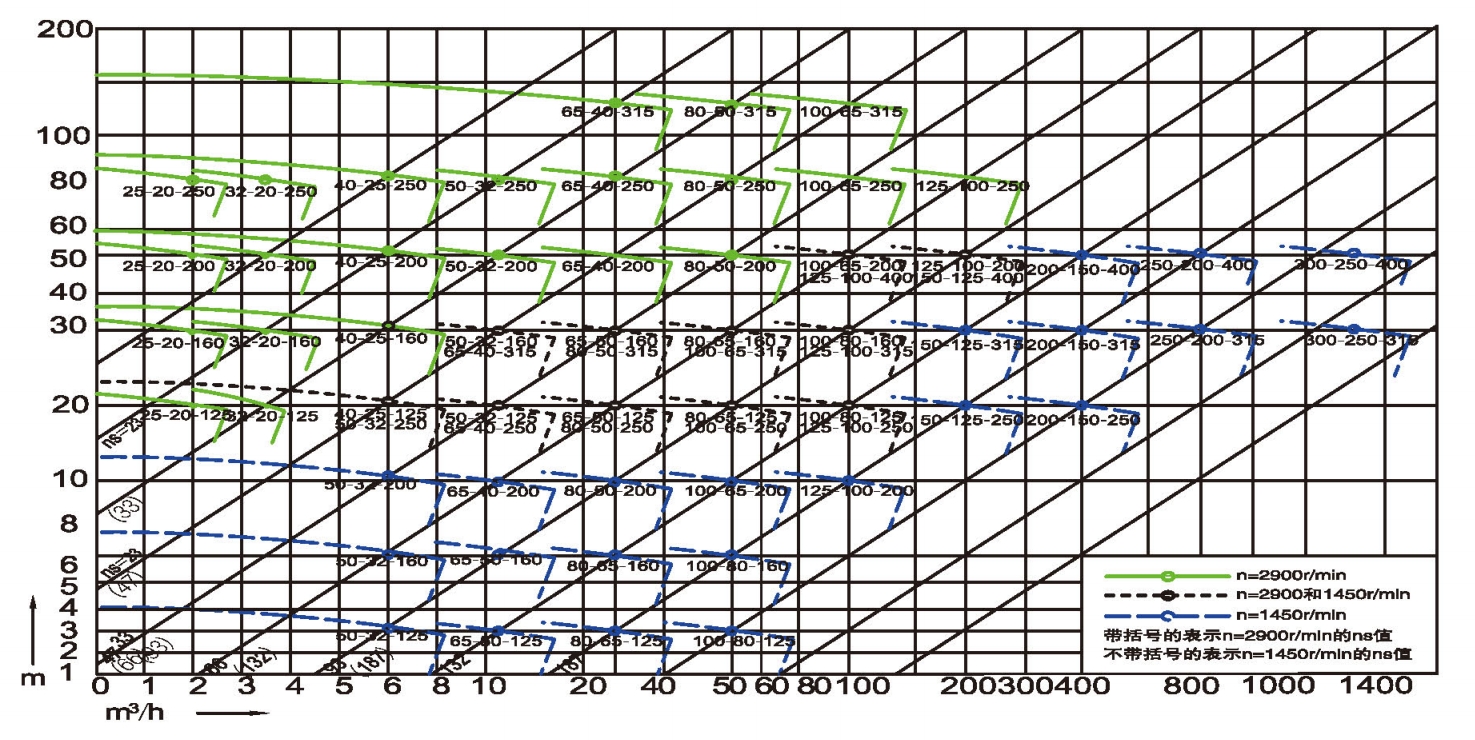

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 25-20-125 | 1.1 | 2.5 | 20 | 380V | 304/316L | 25-20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | 304/316L | 25-20 |

| 25-20-200 | 4 | 2.5 | 50 | 380V | 304/316L | 25-20 |

| 25-20-250 | 1.5 | 2.5 | 80 | 380V | 304/316L | 32-20 |

| 32-20-125 | 1.5 | 3.2 | 20 | 380V | 304/316L | 32-20 |

| 32-20-160 | 2.2 | 3.2 | 32 | 380V | 304/316L | 32-20 |

| 32-20-200 | 4 | 3.2 | 50 | 380V | 304/316L | 32-20 |

| 32-20-250 | 7.5 | 3.2 | 80 | 380V | 304/316L | 32-20 |

| 40-25-125 | 1.5 | 6.3 | 20 | 380V | 304/316L | 40-25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | 304/316L | 40-25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | 304/316L | 40-25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | 304/316L | 40-25 |

| 50-32-125 | 2.2 | 12.5 | 20 | 380V | 304/316L | 50-32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | 304/316L | 50-32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | 304/316L | 50-32 |

| 50-32-250 | 11 | 12.5 | 80 | 380V | 304/316L | 50-32 |

| 65-50-125 | 3 | 25 | 20 | 380V | 304/316L | 65-50 |

| 65-50-160 | 5.5 | 25 | 32 | 380V | 304/316L | 65-50 |

| 65-40-200 | 11 | 25 | 50 | 380V | 304/316L | 65-40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | 304/316L | 65-40 |

| 65-40-315 | 30 | 25 | 125 | 380V | 304/316L | 65-40 |

| 80-65-125 | 5.5 | 50 | 20 | 380V | 304/316L | 80-65 |

| 80-65-160 | 11 | 50 | 32 | 380V | 304/316L | 80-65 |

| 80-50-200 | 15 | 50 | 50 | 380V | 304/316L | 80-50 |

| 80-50-250 | 30 | 50 | 80 | 380V | 304/316L | 80-50 |

| 80-50-315 | 45 | 50 | 125 | 380V | 304/316L | 80-50 |

| 100-80-125 | 11 | 100 | 20 | 380V | 304/316L | 100-80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | 304/316L | 100-80 |

| 100-65-200 | 30 | 100 | 50 | 380V | 304/316L | 100-65 |

| 100-65-250 | 45 | 100 | 80 | 380V | 304/316L | 100-65 |

| 100-65-315 | 75 | 100 | 125 | 380V | 304/316L | 100-65 |

| 125-80-160 | 30 | 160 | 32 | 380V | 304/316L | 125-80 |

| 125-100-200 | 55 | 200 | 50 | 380V | 304/316L | 125-100 |

| 125-100-250 | 75 | 200 | 80 | 380V | 304/316L | 125-100 |

| 125-100-315 | 22 | 200 | 125 | 380V | 304/316L | 125-100 |

| 125-100-400 | 30 | 200 | 50 | 380V | 304/316L | 125-100 |

| 150-125-250 | 18.5 | 200 | 20 | 380V | 304/316L | 150-125 |

| 150-125-315 | 30 | 200 | 32 | 380V | 304/316L | 150-125 |

| 150-125-400 | 45 | 200 | 50 | 380V | 304/316L | 150-125 |

| 200-150-250 | 37 | 400 | 20 | 380V | 304/316L | 200-150 |

| 200-150-315 | 45 | 400 | 32 | 380V | 304/316L | 200-150 |

| 200-150-400 | 75 | 400 | 50 | 380V | 304/316L | 200-150 |

| 250-200-250 | 55 | 800 | 50 | 380V | 304/316L | 250-200 |

| 250-200-315 | 110 | 800 | 80 | 380V | 304/316L | 250-200 |

| 250-200-400 | 160 | 800 | 50 | 380V | 304/316L | 250-200 |

| 300-250-315 | 160 | 1400 | 32 | 380V | 304/316L | 300-250 |

| 300-250-400 | 200 | 1400 | 50 | 380V | 304/316L | 300-250 |